1. Equipment IntroductionThe high-concentration bleaching tower is a device used for the peroxide bleaching reaction of high-concentration pulp (28%-32%) from wood pulp and other types of pulp.After the pulp and bleaching liquid are thoroughly mixed in the high-concentration mixer, they enter the bleaching tower. The pulp falls from the top of the tower through the pulp distributor and takes two hours to travel from the top to the bottom of the tower, where it is discharged from the spiral unloading device at the bottom and enters the pulp storage tank, completing the entire high-concentration peroxide bleaching process.

2. Working PrincipleThis equipment uses a conical structure to reduce the possibility of pulp bridging. The top of the tower is equipped with a pulp distributor to minimize the natural angle of accumulation of the pulp; the bottom of the tower has a discharge screw with a constant pitch, constant outer diameter, and variable core shaft diameter to ensure the uniform fall of the pulp across different height sections of the tower, thereby maintaining a consistent residence time for the pulp throughout the high-concentration peroxide bleaching process in all parts of the tower.

3. Equipment AdvantagesThis equipment features an advanced structure, reliable operation, high production capacity, good bleaching effect, wide process adaptability, and easy operation and maintenance.

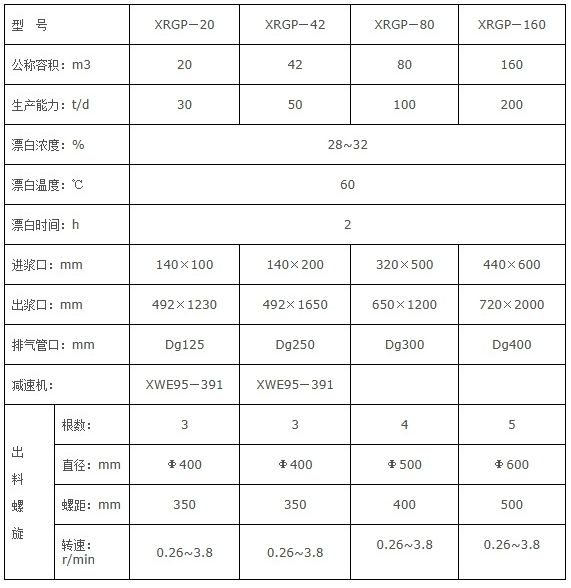

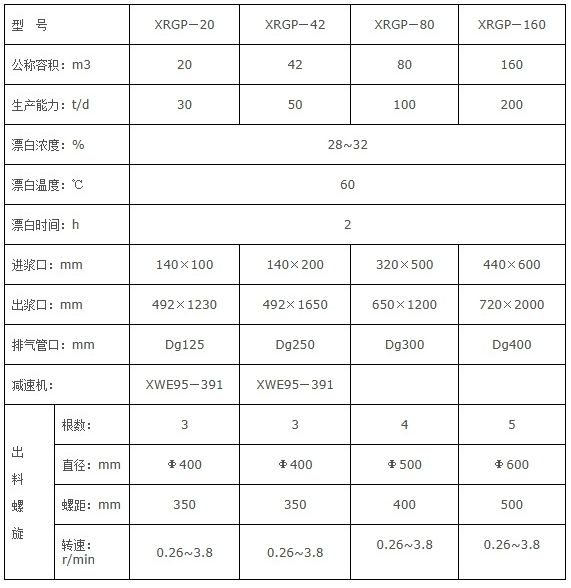

4. Parameter Selection

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)