1. Product introduction

This product is developed by our company on the basis of years of practice, combined with the actual situation of our country's pulp and paper industry, and is a reasonable extraction equipment for the comprehensive utilization of black liquor in the pulp and paper mill.

It can also be used for organic matter dewatering in the food waste industry and manure dehydration in the breeding industry.

This machine is mainly used for the black liquor extraction of wood pulp, bamboo pulp and wheat straw pulp after steaming balls and soaking pools and the slurry concentration of recycled waste paper. After years of use, the equipment has met the required concentration requirements and environmental protection requirements for black liquor extraction.

2. Working principle

After the slurry is steamed through the steaming ball or soaking tank, it enters the slurry extruder, and the water or black liquor is squeezed out under the action of extrusion, so as to achieve the purpose of black liquor extraction. At the same time, because the slurry is squeezed, it also produces a de facto relief effect.

3. Advantages of equipment

1. The machine adopts a single spiral structure, with adjustable slurry concentration, large equipment production capacity and high black liquor extraction rate.

2. The single helix structure has a large extrusion capacity, strong fiber relief effect, and high washing quality.

3. The stainless steel sieve plate structure is adopted, which improves the pore opening rate, reduces the pore size, and reduces fiber loss.

4. The equipment has a simple structure and is easy to maintain and manage.

5. The equipment occupies a small area and is easy to install.

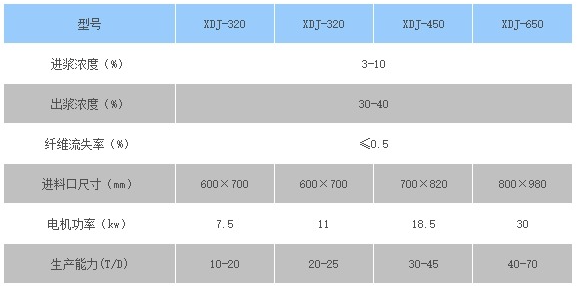

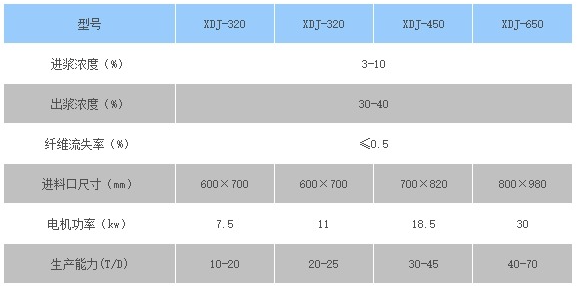

4. Parameter selection

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)