1. Product IntroductionThe XNP type disc concentrator main unit is used for the washing and concentration of low-consistency pulp in the pulp and paper industry.This machine consists of a trough body, disc, drive spindle, upper cover, and spray pipe, among other components. The disc is mounted on the drive spindle and is covered with a stainless steel mesh. As the spindle rotates, the pulp is adsorbed onto the disc, and the concentrated pulp is washed off with high-pressure water, flowing into the pulp zone within the trough. The white water passes through the mesh filter into the disc, flowing through the waterway into the hollow spindle, and is discharged from the white water outlet. When the pulp liquid level exceeds the adjustable flap, it overflows into the pulp discharge trough. The spindle speed can be adjusted using a frequency converter, allowing it to be set according to the desired pulp concentration and production capacity.

II. Equipment Structure and PrinciplesThe disk thickener is mainly composed of the tank body, fan disk, drive spindle, upper cover, spraying device, sealing device, motor direct-coupled reducer, protective cover, and other components, as shown in the outline diagram.1. Tank Body: Welded from steel plates and profiles, the part in contact with the slurry is made of stainless steel. The rotating drum is placed inside the tank body, supported by bearing supports at both ends of the tank body. One side of the tank body is the slurry inlet, and the other side is the slurry outlet, where there are white water outlets and sewage outlets on the wall panel. A gate valve is also installed on the slurry outlet side to adjust the tank.2. Fan Disk: Made from welded stainless steel perforated plates, it contains a water channel inside; the outer surface is covered with 40-mesh stainless steel wire mesh.3. Drive Spindle: Besides transmitting power, it also serves to install the fan disk and output white water. It has internal water pathways to quickly discharge the white water filtered by the fan disk.4. Upper Cover: Welded from stainless steel with an observation hole opened on top.5. Spraying Device: Composed of water inlet pipe support, spray pipe, and ball valve, it is used to strip the slurry from the fan disk and wash the stainless steel wire mesh. The pressure of the washing water should be greater than or equal to 0.3Mpa, and the water requirement for each set of fan disks is approximately 160L/min.

3. Advantages of the EquipmentCompared with the existing gravity circular net concentrators, the pan-type concentrators have a volume that is 4-5 times smaller for the same nominal area. They feature a compact structure, small footprint, easy assembly and disassembly of the disk, corrosion resistance, reliable operation, and easy maintenance.

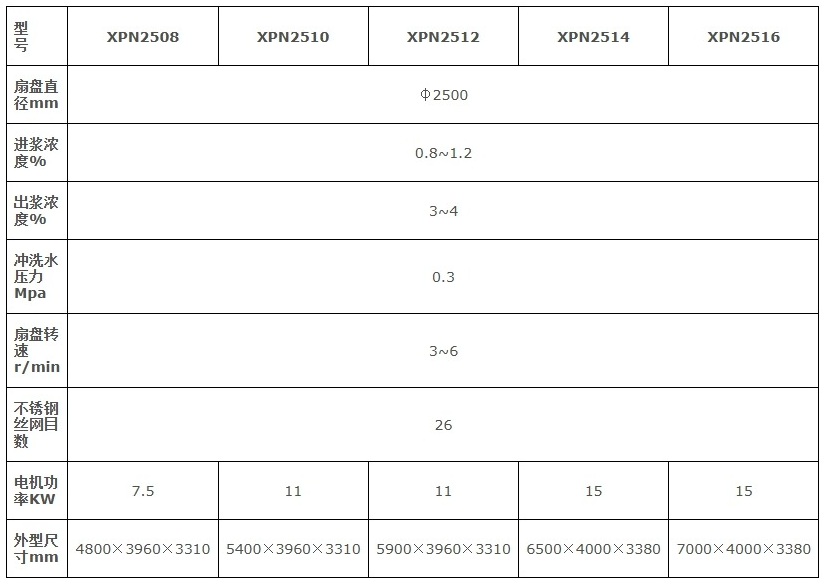

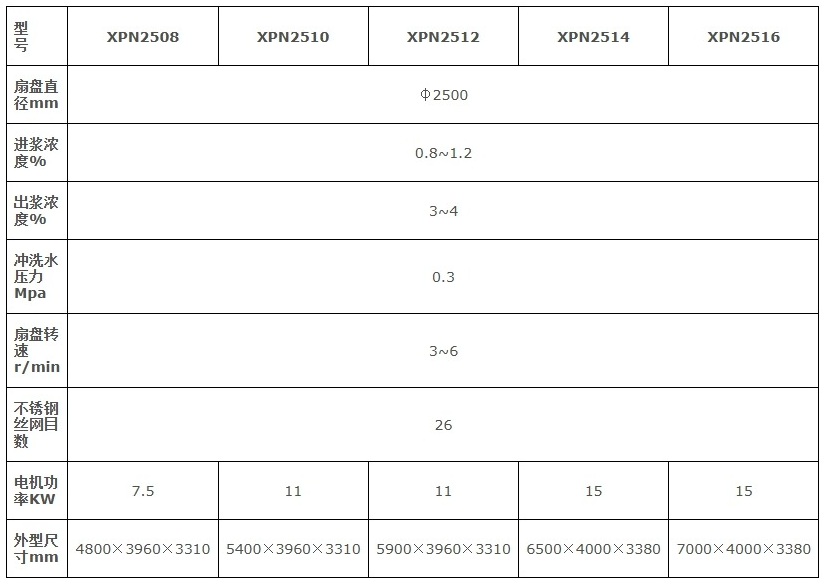

4. Parameter Selection

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)