1. Product IntroductionThe ZDYA series belt filter press is a new type of slurry dewatering equipment developed by our company's researchers based on advanced technology from the United States, referencing similar domestic products, while digesting and absorbing their shortcomings and advantages. It can be used for the concentration and washing of slurries and can be connected in series for multiple washing stages.In addition to the ability to produce continuously, simple operation, and requiring fewer auxiliary devices, this series of products has significant advantages such as large processing capacity, high dewatering efficiency, easier operation, low investment and energy consumption, and maintenance costs, making it suitable for various slurries. It is a new type of solid-liquid separation equipment.

2. Working PrincipleThe filter press is divided into three working areas.1. Gravity Dewatering ZoneThe slurry is pumped into the filter press and then flows by gravity into the fabric distribution device of the filter press, distributing the slurry evenly on the filter belt. The filter belt in the gravity dewatering zone travels horizontally, and the capillary water of the conditioned slurry turns into free water, which is separated from the slurry under the influence of gravity. The function of the gravity dewatering zone is to increase the slurry concentration and stabilize the slurry for the subsequent squeezing and dewatering.2. Pressure Dewatering ZoneIn this area, the upper and lower filter belts gradually come together, and the slurry is gradually squeezed, continuing to increase in concentration.3. Pressurized Dewatering ZoneEntering the pressurized dewatering zone, the slurry trapped between the upper and lower filter belts moves up and down in an S-shaped manner between seven S-shaped arranged squeezing rollers. The gradually increasing pressure and shear force squeeze out the capillary-bound water from the slurry, producing drier pulp, which is discharged outside the machine by the scraping device, completing the entire dewatering process.

3. Equipment Advantages1. Continuous operation, stepless speed regulation, large production capacity, low energy consumption;2. Simple operation, convenient maintenance, long service life;3. High dewatering efficiency, high fiber content in pulp;4. Low noise, low reagent usage, economical and reliable, widely applicable.

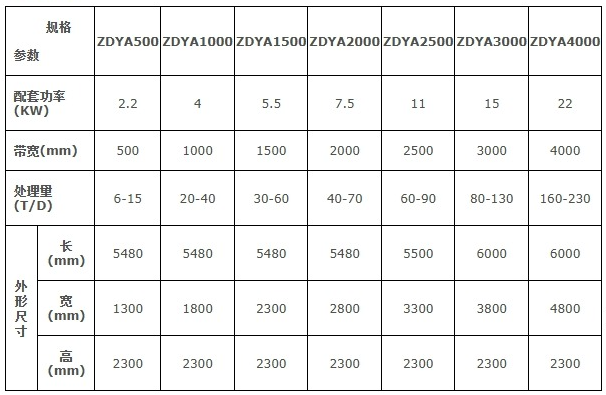

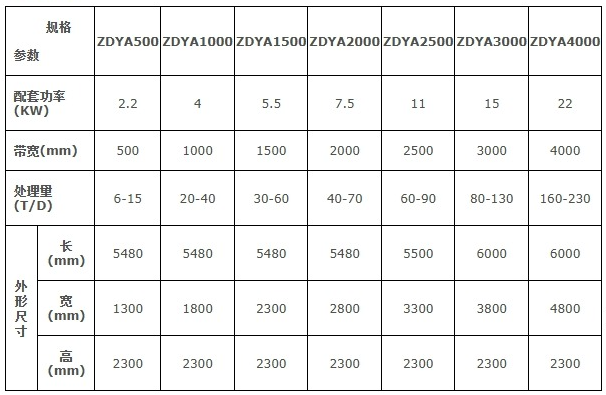

4. Parameter Selection

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)