1. Equipment IntroductionThe inclined spiral concentrator is the latest generation of advanced equipment for pulp concentration and washing technology. It is designed based on the production realities of grass pulp and waste paper pulp in China. It was developed by our factory's engineering technicians who referenced relevant foreign materials and absorbed imported products for the pulping and paper-making industry to concentrate, wash, and separate various types of pulp, especially suitable for dewatering and concentrating waste paper pulp. The inclined spiral concentrator can be used individually or in series to meet the high concentration requirements of subsequent equipment as well as environmental requirements for black liquor extraction.This machine is characterized by its large production capacity, high dewatering efficiency, small footprint, and convenient operation and maintenance.Low-concentration pulp enters through the feeding port into the porous pipe, which is pushed to transport it upward from the bottom by the spiral. Wastewater flows into the box from the porous pipe due to gravity and is discharged from the white water outlet, while the concentrated pulp is discharged from the upper pulp outlet.

2. Main Structure1. This equipment mainly consists of a feeding port, base, water blocking plate, screening drum, spiral shaft, reducer, etc. The feeding baffle and screening drum are securely and accurately assembled on the base, with the spiral shaft rotating inside the screening drum.2. To facilitate inspection and maintenance, the porous pipe adopts a partial structure. The porous pipe is made of stainless steel.3. The design of the spiral aims to prevent clogging and achieve efficient concentration. To improve the concentration of the pulp, it has been changed to a non-equidistant spiral, and the spiral shaft is made of Q235-A plate and 45# steel. It is equipped with axial movement and spiral components as well as a pulp breaker for smooth pulp discharge.4. To make the structure of the equipment compact, the spiral shaft adopts a large modulus gear for speed reduction (reversing) transmission, which is durable and easy to repair, with an accurate transmission ratio.

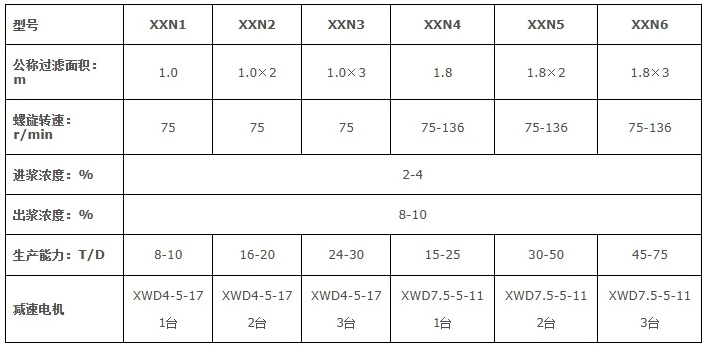

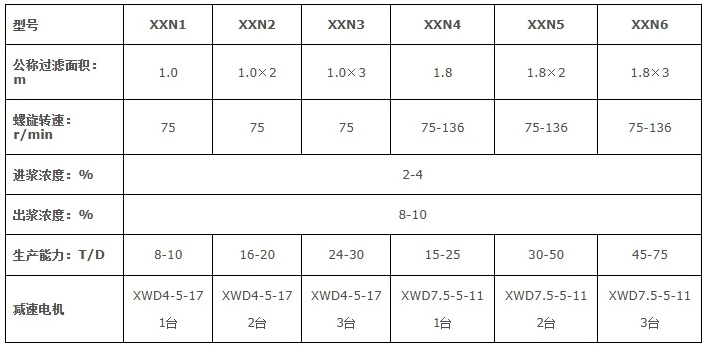

3. Parameter Selection

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)