1.Product IntroductionThe gravity-type round screen concentrator is used in the pulping and paper-making industry for the dehydration and concentration of low-concentration pulp. It is suitable for the dehydration and concentration of wood pulp, cotton pulp, rice straw pulp, and can also be used in non-paper industries to filter and concentrate other types of fiber suspensions. Compared with existing pulp concentration equipment, it has advantages such as simple equipment structure, convenient installation and maintenance, high production capacity, and wide applicability of pulp types, making it widely adopted in the pulping and paper-making industry.Main StructureThis machine mainly consists of a trough body, a rotary drum, a pressing roller, a pressing frame, a scraping device, a swinging spray pipe, a sealing device, and transmission components.1. Trough BodyThe trough body supports all components except for the drive part and is made of steel plates and profiles welded together. The mesh trough is essentially countercurrent, with the center of the mesh trough offset from the center of the rotary drum. Below 15m it is 80mm, and above 20m it is 100mm. The slurry enters the trough body from the inlet located at the lower part of the mesh trough, allowing some of the slurry to directly reach the bottom of the mesh trough, which can dilute the concentrated slurry at the bottom, sometimes helping to eliminate slurry accumulation and facilitating the dehydration of the slurry onto the mesh. It is also equipped with a slurry outlet and a white water outlet.The discharge water level can be adjusted with a gate to control the liquid level difference between the inside and outside of the mesh trough.

2. The rotary drum has two forms:(1) The rotary drum adopts a wheel rim structure with an additional polypropylene injection molded filter plate. This filter plate structure utilizes effective new technologies that have emerged in recent years, offering advantages such as lightweight, corrosion resistance, long lifespan, and ease of maintenance compared to the previously used wire-wound mesh cage.(2) The rotary drum employs a wheel rim structure with stainless steel plate inlays. This structure utilizes the latest technological advancements, making it more advanced than the previously used wire-wound type. It boasts advantages such as corrosion resistance, long lifespan, and good dewatering performance.The surface mesh of the rotary drum is customizable, with the material and specifications determined and formulated by the user according to the type of slurry and processing conditions. For filtering and concentrating pulp in the pulp and paper industry, a nylon mesh with a specification of 40 mesh/hour is typically selected.The wheel rim of the rotary drum is fixed to a hollow shaft, supported at both ends by standard bearing housings that are fixed to the tank body.The rotary drum is driven by an electromagnetic speed-regulating asynchronous motor via a V-belt and a gearbox, allowing users to select the optimal drum rotation speed based on production needs.3. Press Roller SectionA press roller is installed above the rotary drum to provide final forced dewatering of the slurry. The dewatered and concentrated slurry is then adhered to the rubber-covered surface of the press roller. It is scraped off by a knife and falls into the discharge trough for discharge. The pressing force of the press roller against the rotary drum is generally controlled to around 10 N/cm. The appropriate line pressure of the press roller can be selected by adjusting the length of the supporting spring, based on the slurry and the thickness of the slurry layer. The slurry can be drawn out of the slurry tank using the sliding board on the tank body.4. Screen Washing DeviceThe screen washing device features a swinging wash pipe driven independently by an A-type reducer, enhancing the cleaning effect of the concentrator mesh, thereby improving concentration efficiency.

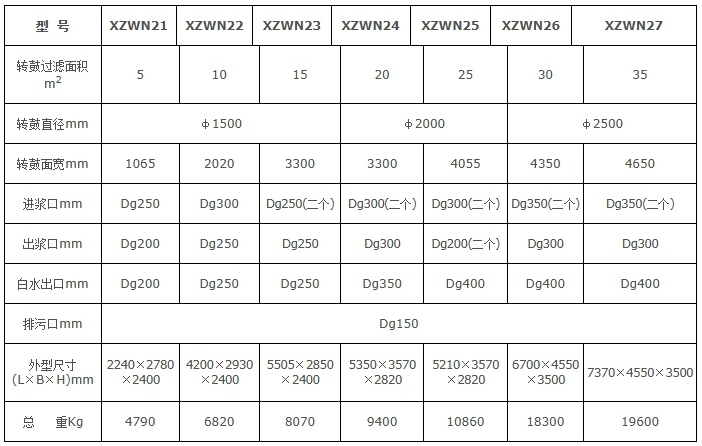

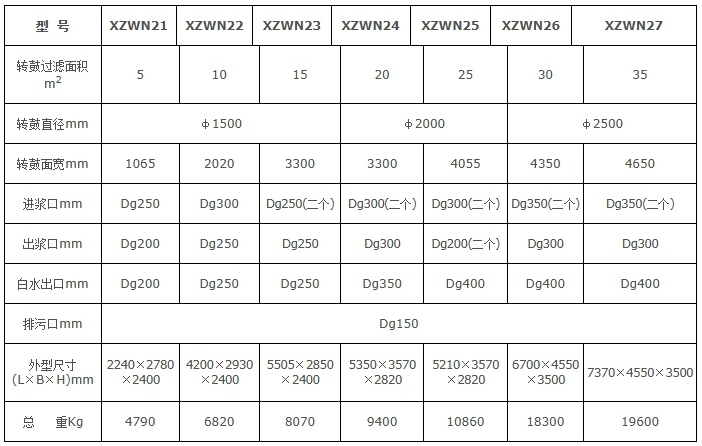

3. Parameter Selection

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)