1. Product IntroductionFor waste paper pulping and papermaking enterprises, the washing and concentration of pulp is as critical as chemical pulping. Existing washing and concentration equipment for waste paper pulping generally uses the washing and concentration equipment designed for chemical pulping. However, due to the differences in the physical form of the washing targets (the washing target in chemical pulping is various liquid organic substances dissolved in pulp, while in waste paper pulping, it includes non-fibrous solid substances adhered to fibers or free between fibers, such as ink, filler dust, etc.), using the same pulp washing equipment will inevitably reduce the washing efficiency. The XGX high-speed pulping machine is the latest generation of washing and concentration equipment specifically designed for the washing and concentration of waste paper pulp, particularly waste paper de-inking pulp.This equipment has a very high removal efficiency for ink particles, fillers, and other small impurities in the pulp and can be widely used for the washing and concentration of recycled pulps from waste newsprint, used account book paper, and old publication paper.

2. Working PrincipleThe high-speed pulping machine sends the pulp through a flow box into the gap between the polyester mesh and the chest roll. The chest roll drives the mesh and the press roll to rotate at high speed, causing the pulp to be subjected to the combined effects of the squeeze pressure from the mesh and chest roll and the centrifugal force generated by the high-speed rotation, enabling the pulp to be dewatered and washed. As the pulp reaches the press roll with the mesh, it is further dewatered by the squeeze and centrifugal force from the mesh and the press roll, and then scraped off by a blade into the discharge spiral. During this process, due to the thin layer of pulp between the mesh and the rolls, the barriers faced by ink particles, fillers, and other small impurities when exiting are minimal, allowing them to easily exit with the water.

3. Equipment Characteristics1. High impurity removal efficiencyThe layer of material between the polyester screen and the roller is very thin, resulting in a short travel distance for impurities to be removed from the slurry. The hindrance effect from the slurry layer during the removal process is minimal, and the centrifugal force generated by the high-speed operation makes it easy for small impurities like fillers and ink particles to be removed, achieving a removal rate of over 99% for ash content in the washed slurry.2. High dewatering efficiencyThe extremely thin slurry layer and high centrifugal force not only facilitate the removal of small impurities but also aid in moisture removal. The device features a lower slurry concentration at intake and a higher concentration at discharge, achieving a dewatering rate of over 90% for the washed slurry.3. Uniform quality of washed slurryThe lower intake concentration and the uniform slurry distribution provided by the inlet system ensure a consistent distribution of the slurry in any direction. Coupled with the constant extrusion pressure and centrifugal force during the dewatering process, the slurry maintains a uniform dewatering momentum, resulting in stable and consistent output quality.

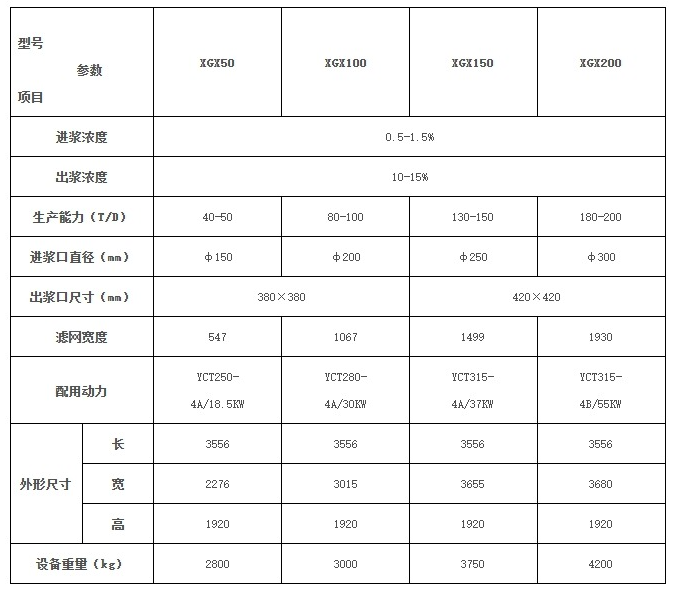

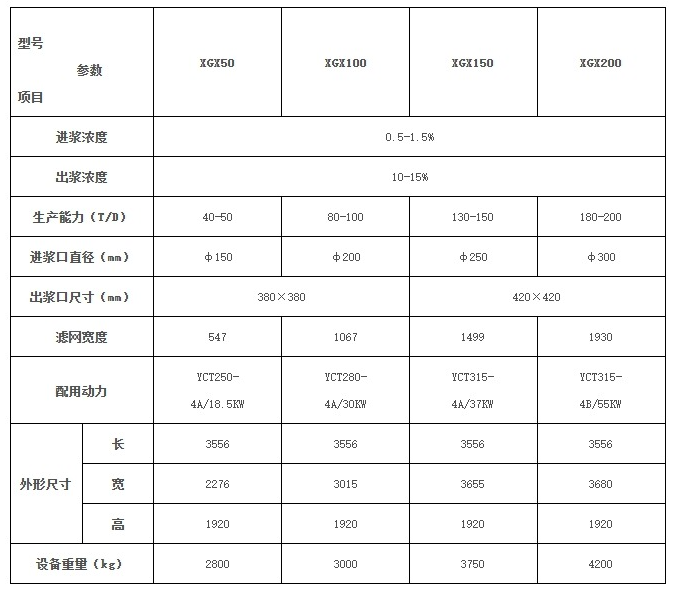

4. Parameter Selection

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)