1. Product IntroductionThis equipment is the latest generation of black liquor extraction and pulping washing equipment developed by our factory based on the introduction and digestion of advanced foreign technology. It features low power consumption (only one-twentieth of other washing and pulping equipment), low equipment cost, small dilution factor, low pulp concentration (suitable for about 2%), high pulp concentration (can reach over 25%), and extremely low fiber loss rate. It is an upgraded product of various existing black liquor extraction and pulping washing devices, especially different horizontal belt and spiral mesh belt pulping equipment.

2. Working PrincipleBased on the functions of various parts of this equipment, the entire washing and dewatering process can be divided into two parts: the pre-press dewatering zone and the pressurized dewatering zone. The pulp is evenly distributed on the lower mesh by the pulp spreader and enters the pre-press dewatering zone, where the pulp removes most of the free water. It is then sandwiched between the upper and lower meshes and enters the pressurized dewatering zone. In this area, the pulp held by the double mesh is compressed in the thickness direction as it passes through the dewatering rollers, achieving forced dewatering. At the same time, the upper and lower meshes are held apart by a rod between the two dewatering rollers, continuously rinsing the pulp with washing water, and then using a vibrating rod to agitate the pulp on the mesh, allowing the cell walls of the fibers and the black liquor within the cells to continuously diffuse out. The exchanged black liquor is removed in the next dewatering roller. Through multiple exchanges and cycles of forced dewatering, the pulp is thoroughly cleaned. The washing water is reused through a countercurrent washing method, significantly reducing water consumption, increasing black liquor concentration, and facilitating the treatment of wastewater. Finally, after the pulp enters the last dewatering roller and is dewatered, a scraper mounted on the drive lower roller removes the pulp cake, and the filter screen for the pulp is cleaned with high-pressure water before entering the next working cycle.

3. Structural CharacteristicsThis equipment mainly consists of a frame, pulp spreader, driving rollers, dewatering rollers, guiding wire rollers, alignment rollers, tension rollers, and upper and lower wire screens that achieve closed-loop movement supported by the dewatering rollers. In addition, it is also equipped with a wash wire spray pipe, a wash pulp spray pipe, a spray pipe overflow trough, a water collection tank for the dewatering rollers, a vibrating rod, and a self-draining washing water scraper, among others.The driving rollers drive the upper and lower wire screens in a circular motion, with each of the two driving rollers equipped with a scraper. The upper and lower wire screens are tensioned by the tension rollers and aligned by the alignment rollers. The pulp spreader is located above the guiding rollers, and the upper and lower wire screens can overlap as they pass over the dewatering rollers. Each dewatering roller is equipped with a water collection tank and a spray pipe (after pulping, only one dewatering roller does not have a spray pipe), and each spray pipe has an overflow trough below it. Below the mesh that passes through the spray pipe, there is a vibrating rod to facilitate counterflow washing of the pulp. To enhance the dewatering effect of the pulp, the first dewatering roller is designed as a hole roller, facilitating dewatering. Each subsequent dewatering roller is made as a smooth roller, allowing the water sprayed from the spray pipe to penetrate through the entire thickness of the pulp, preventing some washing water from "short-circuiting."The number of dewatering rollers can be designed according to the type of pulp and the required cleanliness of the pulp, generally designed to be between 4 to 15, facilitating 4 to 15 stages of counterflow washing of the pulp.

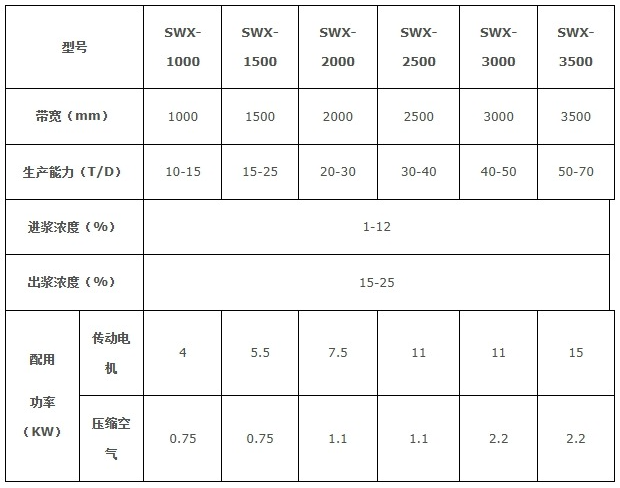

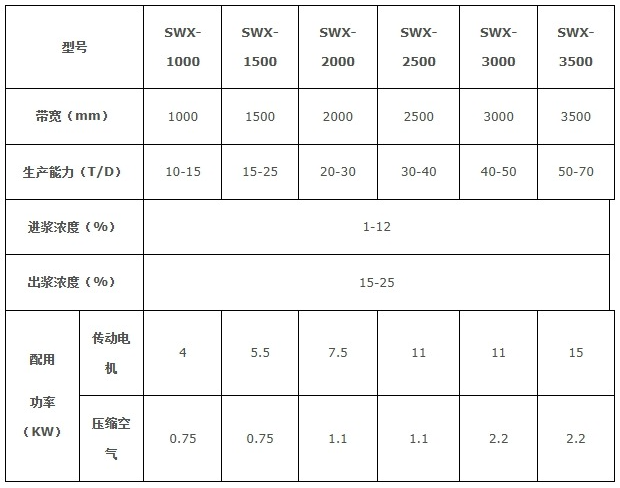

4. Parameter Selection.

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)