1. Product IntroductionThe XLS type liquid filtering pressure screen is used for black liquor filtration in alkali recovery projects within the pulp and paper industry, or for the purification of other wastewater and waste liquids. This machine features a large filtration capacity, high filtrate purity, no fiber hanging on the drum, and ease of operation, making it an upgraded product to replace traditional circular mesh liquid filters.

2. Working PrincipleAfter the paper raw material is processed by alkaline cooking, it is essential to extract the black liquor from the pulp for alkali recovery. However, regardless of the type of black liquor extraction equipment used, there will always be some fibers or various residues present in the black liquor. (This is particularly true when issues occur with the extraction equipment, such as a ruptured filter mesh, damaged pipes, or valves that may lead to higher fiber content in the black liquor). Consequently, during the evaporation and concentration of black liquor, these fibers tend to deposit on the inner walls of the evaporator tubes (or plates), causing scaling and reducing evaporation efficiency. Therefore, before the black liquor is sent to the alkali recovery workshop, it must first be filtered through black liquor filtration equipment to reduce the fiber content to below 60 mg/L to meet the requirements of the evaporation section.The pressure liquid filter operates under pressure with microporous filtration technology, efficiently removing fibers and other solids from the suspension, and features a self-cleaning function to unclog the filter holes. It can be used to filter pulp black liquor, removing fibers from the black liquor to prevent scaling on the evaporator walls. It can also filter white water from paper machines for recycling and fiber recovery, achieving a recovery rate of over 70%. Additionally, it can filter other wastewater from paper mills to remove impurities and reduce the amount of water requiring treatment. This is an excellent environmentally-friendly purification device.

3. Advantages of the Equipment● High clarity of the filtrate.● Filtering is performed under pressure, with a large capacity.● Filter pores do not clog, reliable operation, and easy to operate.● Made of stainless steel, with good corrosion resistance.● Closed operation, no foam odor is generated.● Compact size, easy to install.

4. Applications of the Equipment● Filtering black liquor produced by the alkali method or red liquor produced by the acid method to remove fine fibers.● Filtering white water from paper machines to recover fibers and recycle water.● Purifying mid-stage wastewater from paper mills to reduce the load on the wastewater treatment system.● Filtering recycled water in paper mills to remove impurities and improve water quality.

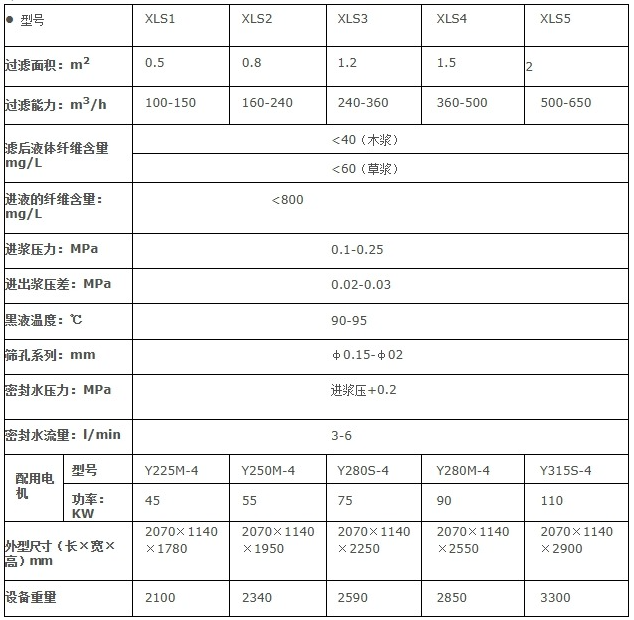

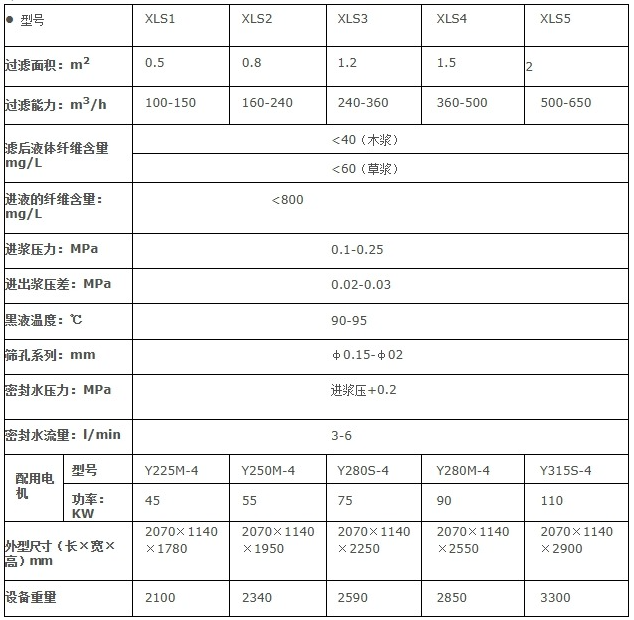

5. Parameter Selection

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)