1. Product IntroductionThe rotary drum pressure screen is the latest generation of in-line pulp screening equipment developed by our company, based on the digestion and absorption of imported foreign technologies and combined with domestic operational practices. It is suitable for screening waste paper pulp and wood pulp, primarily for waste paper pulp screening. This product integrates the functions of screening and purification, effectively removing both light and heavy impurities while performing coarse screening.

2. Working PrincipleThe pulp enters the outside of the screen drum from the bottom of the screen, where the rotating drum generates strong centrifugal forces that throw heavy impurities to the outer edges. The creatively designed elephant trunk-type discharge pipe effectively eliminates heavy impurities, while the tangentially entering dilution water, aided by the pressure difference inside and outside the drum, allows good pulp to pass through the openings of the drum and discharge from the good pulp outlet at the bottom. Light impurities can be discharged from the center of the top cover, achieving the dual functions of removing heavy impurities and coarse screening. This can replace the traditional effects of slag removers and fiber separators.

3. Equipment Advantages1. The rotating screen drum, with its inclined ripple structure and in-line design, facilitates the discharge of heavy slag, achieving a removal rate for heavy impurities superior to that of general high-concentration slag removers, thus ensuring low energy consumption.2. The fixed rotor design results in minimal wear in the good pulp area inside the drum, requiring less maintenance.3. The intermittent discharge of heavy slag is facilitated by the discharge valve, water inflow valve, and exhaust valve on the elephant trunk-type discharge pipe, which can automatically adjust the timing of various actions based on the cleanliness of the raw materials, effectively reducing fiber loss.4. It can effectively remove heavy impurities, provides gentle screening, produces clean pulp, and has low energy consumption, along with reduced maintenance costs.5. Low fiber loss; high screening efficiency; high production capacity; extended service life of the drum.

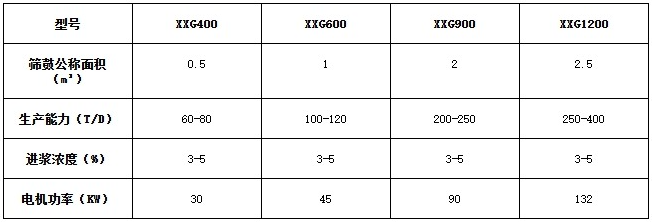

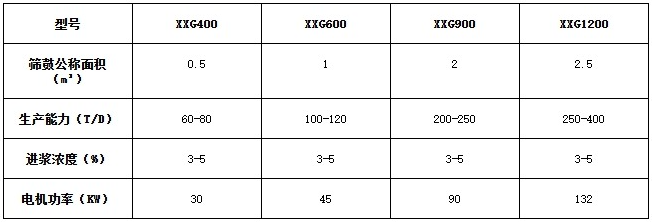

4. Parameter Selection.

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)