1. Product IntroductionThe ZSK series high-frequency vibrating frame screen is mainly used for the coarse selection and purification of slurry and can also be used for the treatment of pressure screen tail slurry. It is a commonly used equipment in the pulp and paper industry. It adopts a screen frame with an eccentric wheel and a flexible connection for transmission. By subjecting the screen frame to high-frequency vibrations, it eliminates plastic particles and other large impurities from the coarse slurry to achieve the purpose of screening.

2. Working PrincipleThe slurry enters the screen frame through the inlet pipe after being fed from the feed box, and the slurry is separated from the impurities through the screen plate. The screened slurry enters the slurry tank and is discharged from the outlet, while the undecomposed fibrous impurities are discharged from the end of the screen frame.This machine adjusts the slurry level in the slurry tank using a slurry level adjustment device. The height of the slurry level affects the pressure difference during the slurry screening and the damping of the screen frame vibrations.The vibration of the screen frame is achieved by two eccentric wheels mounted on the main shaft. The main shaft is directly connected to the motor via a flexible coupling. When the motor drives the main shaft, the two eccentric wheels create a vibrating state for the screen frame. The vibration-damping device supports the screen frame with four springs, which has advantages such as a simple structure, good practicality, and low maintenance. This machine can be divided into left and right mobile phones, and users can adjust according to actual conditions. (Facing the discharge end, if the motor is on the left side of the slurry tank, it is the left mobile phone; if the motor is on the right side, it is the right mobile phone.)

3. Equipment AdvantagesThis equipment uses springs as the vibration-damping device, which has advantages such as a simple structure, convenient maintenance, low production costs, small footprint, and high production efficiency.

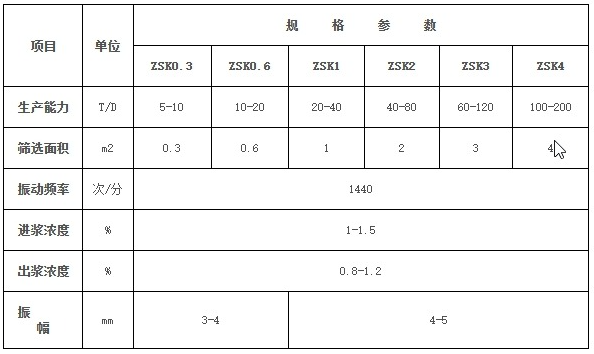

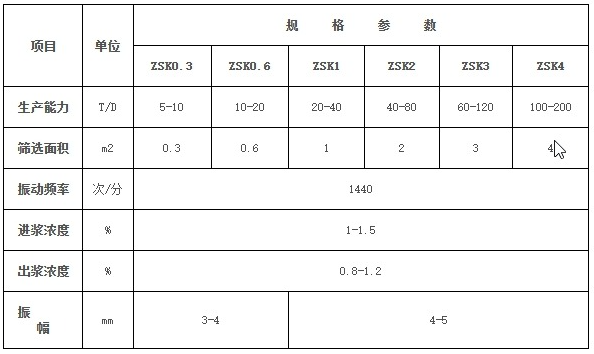

4. Parameter Selection

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)