1. Product IntroductionThe XLNY series internal flow pressure screen is designed based on the digestion of foreign equipment and relevant materials. It is primarily used for screening in the paper machine of the pulp and paper industry, and can also be used for fine screening of various waste paper pulps.The cylinder is made of stainless steel plates, and the rotor has a multi-blade structure. The blades are made of specially treated stainless steel and are evenly distributed on the outer side of the screen drum, featuring high screening efficiency, large throughput, low pulsation, low power consumption, good separation of impurities and fibers, long service life, compact structure, and easy maintenance. It is currently considered an ideal fine screening device. This product plays an important role in improving the grade of finished paper.

2. Working PrincipleThe pulp enters the cavity between the cylinder and the screen drum tangentially. The pressure difference on both sides of the screen drum allows the qualified fibers in the pulp to flow through the screen holes (or slits) into the screen drum and be discharged from the outlet at the bottom. The pulp residue remaining outside the screen drum is expelled through the tailing outlet under the pressure of the pulp and the push of the rotor. The high-speed rotation of the rotor self-cleans the screen drum.

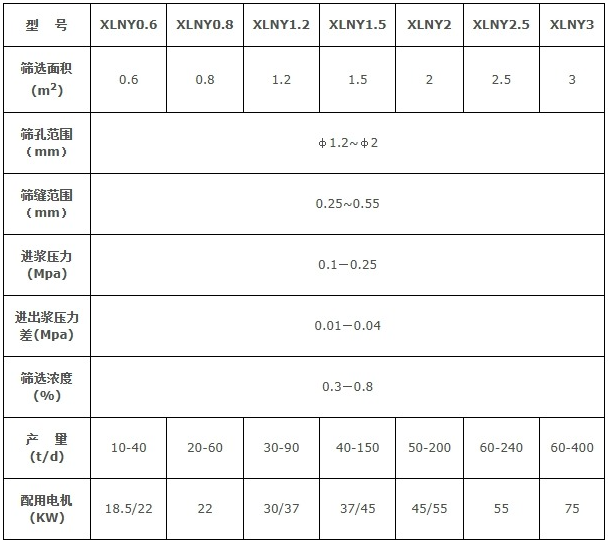

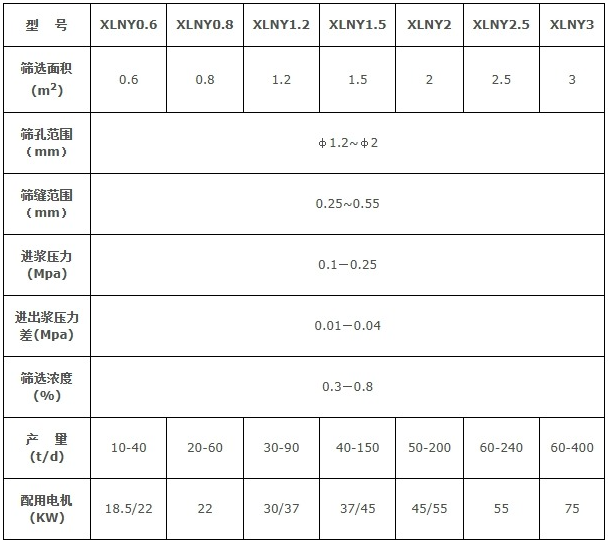

3. Parameter Selection

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)