1. Product Introduction The XRUV-type upward-flow pressure screen is a new type of screening equipment for recycled pulp developed by our factory through the digestion and absorption of imported prototype technology. This device is specifically designed for a rising flow structure, addressing the characteristics of impurities in recycled pulp. It can be widely used for coarse and fine screening of various waste paper pulp, as well as for the screening of pulp before the paper machine. The device boasts unmatched excellent performance and reliability, making it a replacement product for various domestic pressure screens used in recycled pulp processing.

2. Working Principle: It is well-known that the impurities in recycled pulp can be categorized into light and heavy impurities. Traditional pressure screens introduce pulp from the top and discharge waste from the bottom, allowing both light and heavy impurities to pass through the screening area. When processing chemical pulp, the specific gravity and quality of the impurities are generally greater than that of a single fiber, which helps to reduce the retention time of impurities within the equipment. However, when processing recycled pulp containing a significant amount of lighter impurities, this structure can greatly prolong the retention time of the light impurities in the equipment, leading to decreased screening efficiency and increased wear or even damage to the rotor and screen cylinder. The UV-type pressure screen adopts a bottom feed, bottom heavy waste discharge, and top light waste discharge upward-flow structure design, effectively solving the aforementioned issues. Light impurities and air naturally rise to the top discharge outlet, while heavy impurities settle at the bottom discharge outlet as soon as they enter the machine body. This design effectively shortens the retention time of impurities in the screening area, lowers the possibility of impurity recirculation, and enhances screening efficiency. Additionally, it prevents damage to the rotor and screen drum caused by heavy impurities, thus prolonging the service life of the equipment.

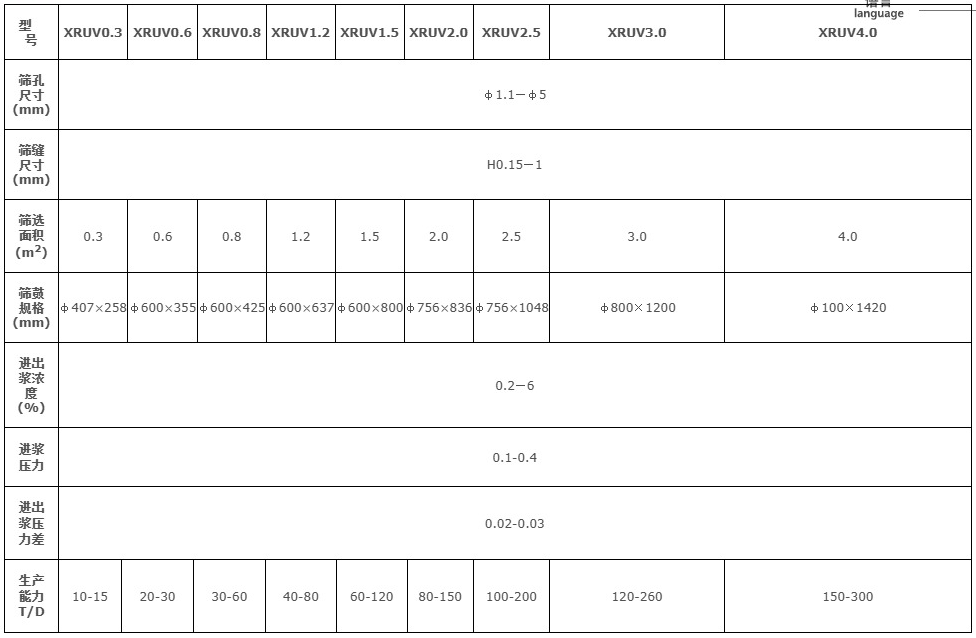

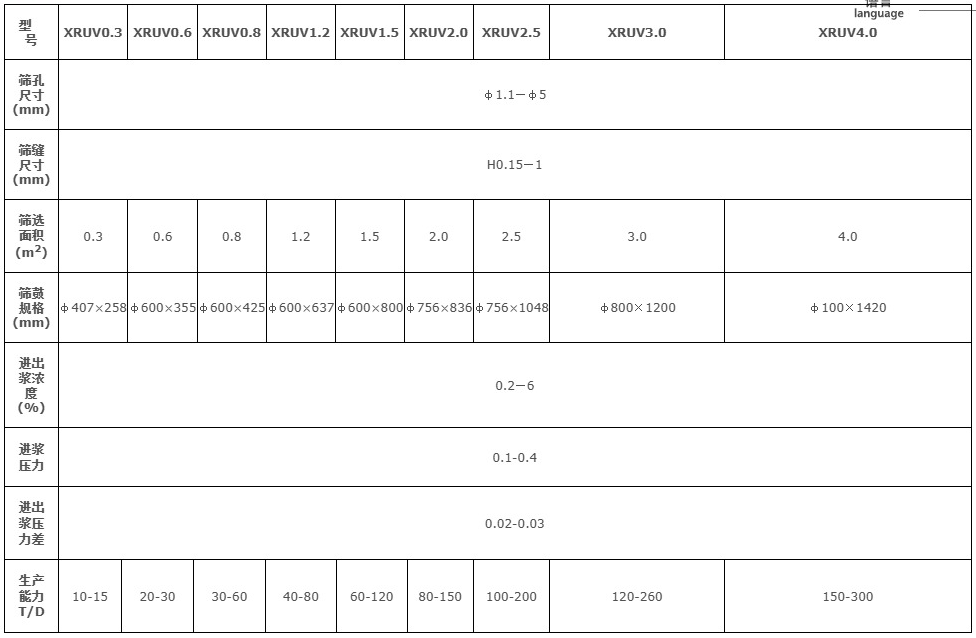

3. Advantages of the Equipment: 1. The precision screen drum, with a width of 0.15mm, is installed after the coarse screen, effectively removing fine impurities in the pulp and ink particles larger than 200um. Notably, the removal rate of adhesive substances in the pulp can reach over 90%, making this technology the most praised substitute for various thermal dispersion equipment in the industry (for a comparative study of the seam screen selection method and the thermal dispersion method regarding adhesive issues, refer to Professor Chen Jiaxiang's article in the third issue of "Paper and Pulp" published in 2000, detailing the application of seam screens as a replacement for dispersers in waste paper systems). 2. Heavy impurities are discharged into a heavy impurity tank at the bottom of the screen body, preventing wear and damage to the rotor and screen drum, thereby reducing downtime. 3. Light impurities and air are rapidly discharged from the top tail pulp outlet. 4. High screening efficiency with a short retention time for impurities in the screening area significantly reduces the possibility of impurity recirculation. 5. Low required pulp feeding pressure. 4. Parameter Selection

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)