1. Product IntroductionThe ZSM series dual-drum low-pulse pre-screen is a new product that incorporates technology from Andritz-Ostron Company. It is a core component of the modern paper machine's pulping system. With its special design and high-precision manufacturing, it achieves low-pulse operation for pre-screens; disperses fiber fillers and papermaking additives, fluidizing them; screens out residual impurities in the pulp and impurities from the broke system, serving as the final quality control. It meets all operational requirements of the paper machine's stock chest. It features stable screening, low pulse, low power consumption, and high screening efficiency.

2. Operating PrinciplePulp is sent tangentially into the upper part of the pre-screen, flowing into the space between the two screening drums. Under the combined action of centrifugal force and centripetal force generated by the rotation of the dual-rotor impeller, good pulp passes through the inner and outer screening drums and collects in the good pulp pipe at the lower end of the screen body for discharge. The rotors keep the screening drums clean while rotating. The pulp residue is pushed axially by the rotation of the rotor, becoming concentrated and gradually moved down to be discharged from the discharge port.

3. Equipment Advantages

Rotors: Special design, easy to install, dual-rotor structure with low-speed design, allows for smooth screening of low pulse net before the screen, minimizing pulses, while saving power and reducing energy consumption.Screen drum: Specially designed ripple screen drum that generates ideal turbulence near the screen seam, maintains a constant distance between the rotor blades and the screen drum to enhance the rotor's purification effect on the screen drum, preventing issues like slurry hanging and flocculation.Good slurry pipe: Specially designed good slurry pipe structure located beneath the screen drum and rotor, allows the screened good slurry to flow from all sides of the screen to the good slurry outlet, ensuring a smooth and pulse-free flow of good slurry.Special manufacturing process effectively prevents the formation of slurry clumps and changes in concentration.

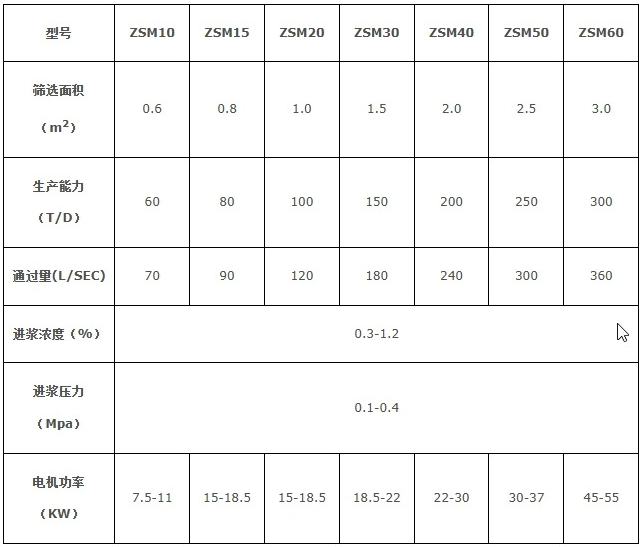

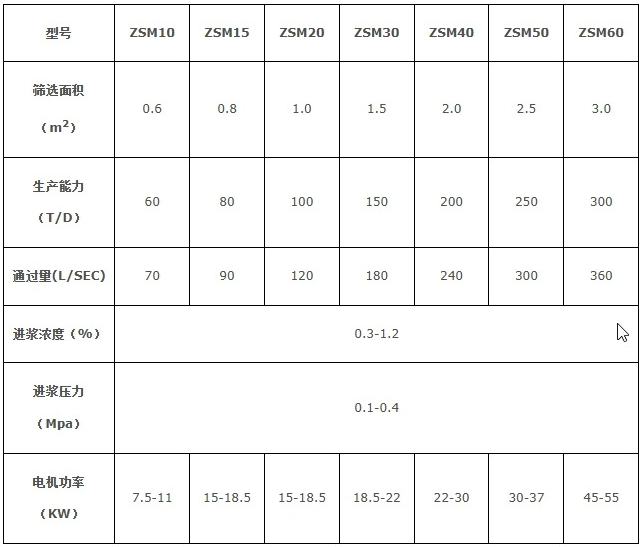

4. Parameter selection.

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)