1. Product IntroductionThe XFS series fiber grading screen is an energy-efficient screening device developed based on foreign prototypes, adapted to China's national conditions. It is primarily used to separate long and short fibers in pulp for effective separate processing and utilization.This fiber grading screen provides a practical, economical, and reliable method for the continuous separation of long and short fibers in pulp. Long or short fibers can be applied separately to multiple products. If only a single product is produced, only the long fibers require refining treatment. Subsequently, they are mixed with short fibers that have had the refining treatment process omitted, thereby obtaining higher quality pulp. When using the XFS series fiber grading screen, the ratio of long to short fibers can be controlled by the size of the screen drum openings, concentration, and hydraulic action.

2. Working PrincipleThe device mainly consists of a screen drum, rotating drum, housing, and drive device. The slurry enters the screen drum tangentially under certain pressure. Under the influence of the internal and external pressure difference and the rotor, short fibers are discharged through the short fiber outlet, while long fibers descend to the bottom and are discharged through the long fiber outlet. A weir cylinder is installed at the upper end of the screen drum to isolate heavy impurities, reducing wear on the screen drum and rotating drum. The rotor uses a multi-rotor low-pulse design, which ensures a consistent slurry flow speed through the screening slots across the entire height of the rotating drum, overcoming the issue of reduced flow speed at the bottom of the screen drum caused by increased pulp concentration in traditional designs. The number, special arrangement, and shape of the rotor blades fluidize the entire screening area, providing uniform pulsing, high screening concentration, large production capacity, and strong fiber grading effectiveness.

III. Advantages of the Equipment

1. Obtain better quality from existing pulp;

2. Better utilize low-cost waste paper and pulp;

3. Improve the overall strength of the pulp;

4. Obtain cleaner short fiber pulp;

5. Improve water filtration performance;

6. Better operational performance and more uniform pulp.

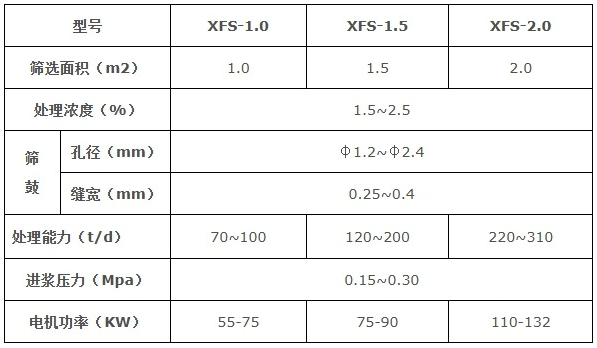

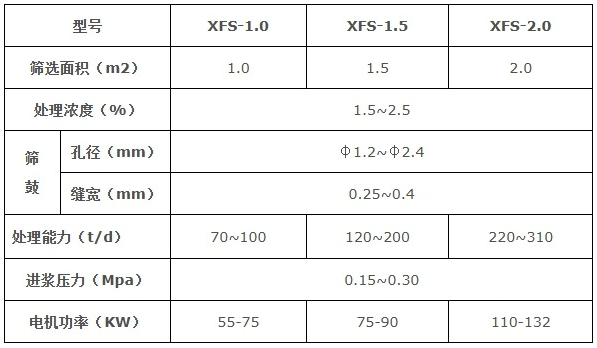

III. Parameter Selection

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)