1. Product IntroductionThe XXS series rotor screen is a pressure screen mainly used in the pulp and paper industry to remove pulp flocs and other non-fiber impurities from the pulp. This equipment has the advantages of high production capacity, high screening efficiency, simple structure, convenient operation and maintenance, small footprint, low noise, and minimal mixing of pulp with air, resulting in less foam. Currently, it replaces other screens for the pre-screening of pulp at the paper machine and is also used for screening chemical pulp and groundwood pulp.

2. Working PrincipleThe working principle is that the pulp coming from the pipeline enters the screening chamber from the top in a tangential direction under a certain pressure. The pulp flows downward due to its own gravity and the drive of the rotor. Due to the pressure difference maintained between the inside and outside of the screening drum, along with the rotation of the rotor, the pulp at the leading edge of the rotor is subjected to pressure, forcing most of the good pulp to quickly flow out through the screen holes. The rotor is streamlined, and as it rotates, the gap between the outer side of the rotor and the inner surface of the screening drum constantly changes, initially narrowing and then gradually widening. Thus, at each moment between the rotor and the screening drum, a pressure zone is formed at the front of the rotor, a balance zone in the middle, and a negative pressure zone at the rear. In the negative pressure zone, the pulp outside the screening drum is drawn back in, helping to scrub the pulp flocs and coarse fibers that adhere to the screen plate, thereby keeping the screen holes clear. When the pulp leaves the trailing edge of the rotor, the negative pressure gradually disappears, and the good pulp is again propelled by another rotor to flow outward, starting the next cycle, while the screening residue falls into the conical outlet at the bottom of the drum and is discharged through the tail pulp pipe.

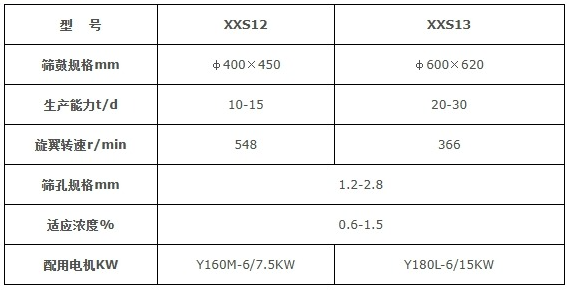

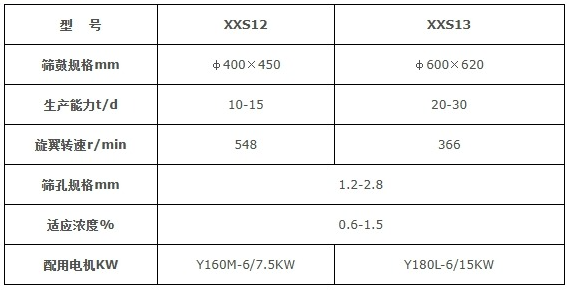

3. Parameter Selection

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)