1. Product IntroductionThe double-disk pulping machine is equipped with technology transferred from abroad, where the pulp enters the center of the grinding zone through two feeding pipes. Under the influence of centrifugal force and feed pressure, it passes through the grinding zone, completing the pulping process through the rubbing and squeezing action of tooth plates within the grinding area. It is suitable for continuous pulping of chemical wood pulp, mechanical pulp, and waste paper pulp, with a suitable pulp concentration of 2-5%. It is equipped with an automatic control system to achieve constant energy consumption or constant power pulping, ensuring stable pulping results.

2. Working PrincipleThe double-disk pulping machine consists of a pulping chamber, transmission mechanism, base, motor, and other components. The pulping chamber is formed by two fixed grinding plates mounted on the machine shell and movable base along with two rotating grinding plates on the rotating disk, creating two grinding zones. By changing the shape of the grinding plates, the machine can be adjusted to meet the pulping requirements of various pulp materials.

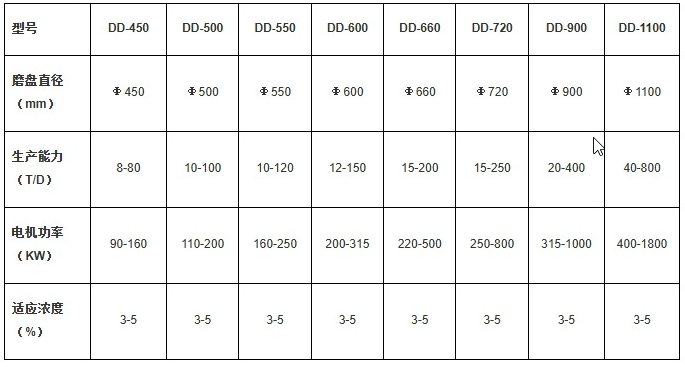

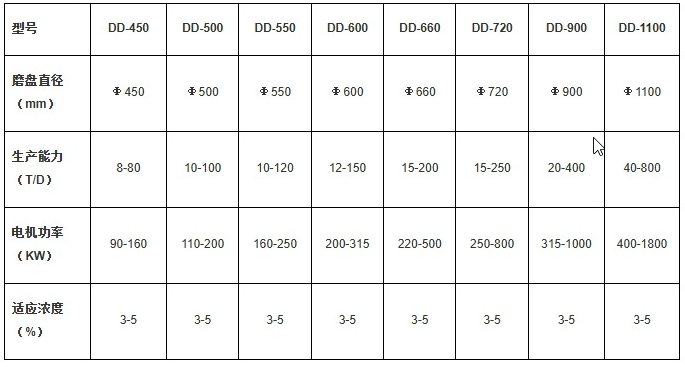

3. Advantages of the EquipmentIt features a compact footprint, high production efficiency, low energy consumption, easy operation, and low maintenance. It is suitable for pulping a variety of pulp materials and is considered an ideal pulping device at present. According to process requirements, this machine can be used individually or in a series of multiple units.4. Parameter Selection

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)