1. Product IntroductionThe ZDPM450, 500, 530, 550, 600, and 750 series medium consistency hydraulic pulpers are a new generation of pulping and grinding equipment for the paper-making industry. They are suitable for continuous pulping and grinding in paper mills, used for treating chemical pulp, semi-chemical pulp, or for grinding high-yield chemical mechanical pulp and mechanical pulp. They can function as pulping equipment for coarse pulp after cooking and washing, and also serve as refining equipment for fine pulp before the paper machine. Suitable for various types of pulp such as waste paper pulp, grass pulp, broadleaf wood pulp, and conifer wood pulp, the pulping and grinding consistency is 6%-12%.2. Working Principle1. The feeding system mainly operates through self-priming feed, which can utilize a hopper or feed tower for self-priming.

2. The pulper is mainly composed of a grinding chamber, fixed disk base, movable grinding disc, spindle, front and rear bearings, adjustment moving device, and pin coupling.Its working principle involves the delivery of the slurry (raw pulp) from a feeding spiral tube by the spooling flaps of the spindle, which flings the slurry into the crushing zone between two circular grinding plates. Then, relying on the high linear speed of the movable disc, the raw pulp is rapidly ground through the coarse and fine grinding zones into a refined slurry, which is then discharged through the outlet into a storage tank for future use.

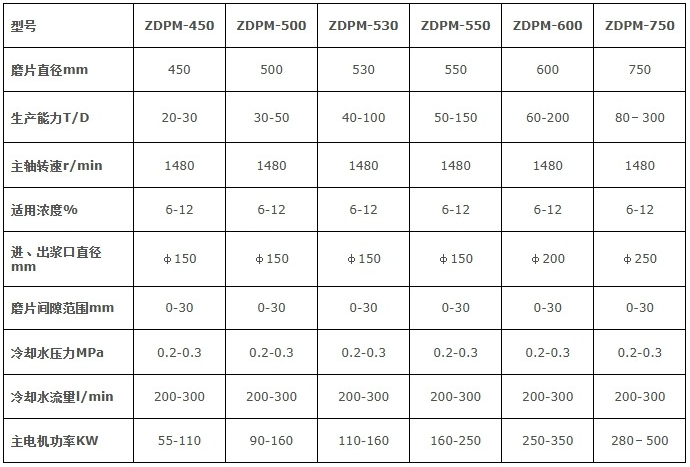

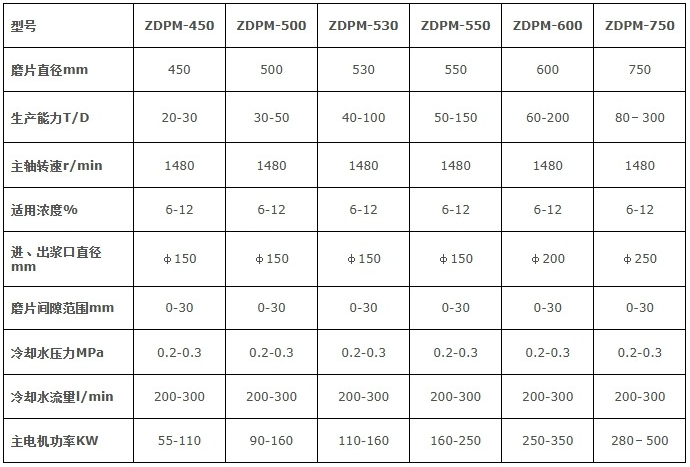

3. Parameter Selection

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)