1. Product IntroductionThe medium-high concentration energy-saving pulping machine, referred to as medium-high concentration grinding, is an upgraded product of medium-high concentration pulping equipment, adopting an electromagnetic speed control forced feeding method. It is suitable for grinding chemical pulp, semi-chemical mechanical pulp, cold soaking high yield pulp, and fiberboard materials.The medium-high concentration grinder has a wide range of applicable pulp materials, whether they are complex tree species, pulp with significant material differences, or leftover edge materials from wood processing, such as wood chips, sawdust, pulp residues, and cold soaking materials like reed, rice straw, wheat straw, and cotton stalks. It can separate them into high-quality fibers with its high rotational linear speed and suitable grinding disc gap.By changing the grinding discs, this pulping machine can also grind seaweed, kelp, giant algae, leather, kitchen waste, animal manure, mushroom spawn, aquaculture feed, shells, and marine waste. Through grinding, materials can be reduced in size or turned into a slurry, serving as high-quality raw materials for producing sodium alginate, animal feed, etc.The medium-high concentration grinder can be used as a single unit, or in series or parallel with multiple units.

2. Main Structure and Working PrincipleThe medium-high concentration mill is mainly composed of a feeding system, a pulping machine, an adjusting moving device, and a motor. Its structure and working principle are as follows:1. The feeding system consists of a feeding motor, a triangular belt wheel, a bearing body, and a feeding spiral tube. The transmission method is: the feeding motor drives the spiral shaft through a triangular belt and belt wheel, and the spiral rotation achieves feeding. The appropriate feeding speed for the medium-high concentration mill is 200r/min-300r/min. Users can adjust the speed control to achieve different feeding speeds for various pulp types according to process requirements.2. The pulping machine mainly consists of a grinding chamber, a fixed disk base, a movable grinding disk, a spindle, front and rear bearings, an adjusting moving device, and a pin coupling. Its working principle involves using the feeding wing wheel of the spindle to fling the pulp (raw pulp) brought by the feeding spiral tube into the crushing area between the two disk plates; then, relying on the rotating linear speed of the movable disk at 2750m/min, it quickly grinds the raw pulp into high-quality pulp in the coarse and fine grinding areas, discharging it through the outlet into the pulp storage tank for later use.The grinding plates are custom-made according to the type of pulp and are specially treated, making them sturdy and durable, highlighting their excellent quality when grinding high-yield pulp using the grinding-soaking method and semi-chemical mechanical pulp.

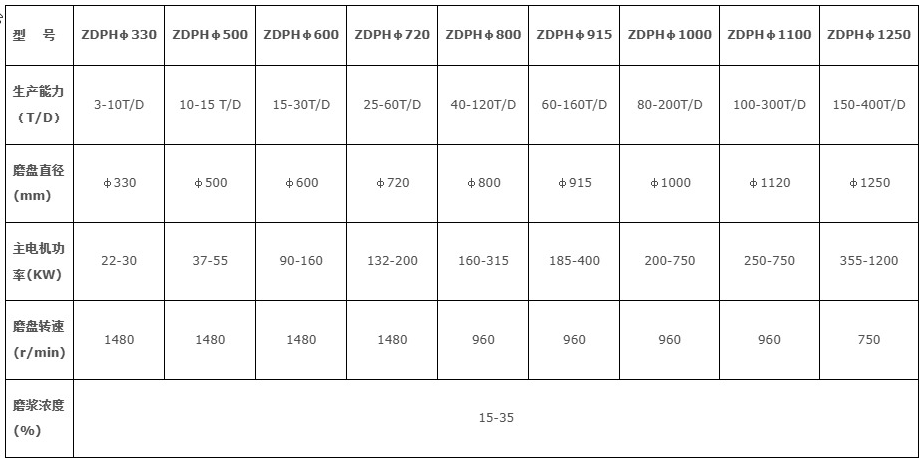

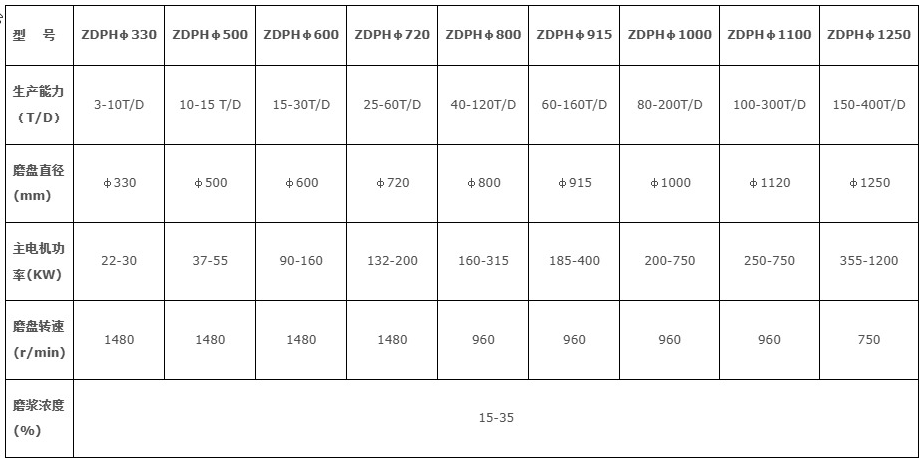

3. Parameter selection.

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)