1. Product IntroductionOur company has introduced the XDLC series high-frequency disintegration machine developed using Japanese technology. This machine integrates pulping, disintegration, and sand removal functions, making it versatile. It effectively disintegrates various fibers such as grass fibers, recycled paper fibers, fiberglass, ceramic fibers, and asbestos fibers, especially excelling in processing high-moisture strong waste paper. The processing efficiency is remarkably high, especially for waste paper like Renminbi notes, invoices, military maps, tableware waste, electronic packaging waste, and stainless steel protective film waste, along with wet-strength paper that includes wet-strength agents, oil-repellent agents, and water-repellent agents. It also eliminates impurities such as sand, stones, and metals.

2. Working PrincipleI. The XDLC I type dual-function high-frequency disintegration machine is modified from the Japanese prototype, with a stator and rotor utilizing a stepped cylindrical design across three grinding zones, and the teeth are welded with YG hard coin alloy. This allows for efficient disintegration of fibers and removal of impurities.II. The XDLC II type is an improved model, where the body has been assembled from components to a whole formation, effectively reducing accumulated assembly errors and ensuring stable disintegration efficiency.III. The XDLC III type is a further improved model, featuring a stepped conical structure in the stator and rotor. It utilizes a worm gear and worm screw gap adjustment mechanism to modify the working gap between the rotor and stator according to the pulping requirements of different slurry types (wood pulp, grass pulp, waste paper), enhancing the equipment's performance, adaptability, and lifespan.IV. The XDLC IV type is vertically installed, occupying only one-third of the floor space of a horizontal machine, making it convenient for maintenance. The sand removal function not only relies on centrifugal force but also utilizes the weight of the sand particles to remove larger impurities. Additionally, the rotor can operate in both clockwise and counterclockwise directions, facilitating improved sand removal efficiency and extending the lifespan of the rotor and stator.

3. Advantages of the Equipment1. Economically and effectively separates various fibers and different types of waste paper raw materials. By adjusting the concentration, pulp supply, and valve control of the pulp flow, it can meet the pulp requirements for different types of paper.2. Significant energy savings, with electricity consumption not exceeding 30 kWh per ton of absolutely dry pulp, and low noise.3. Because the fibers are not cut, there is less production of hemicellulose and low pulp loss, which allows for efficient dewatering of the mesh, improves paper quality, and reduces the amount of mixed pulp and wood pulp used.4. Effectively removes impurities to ensure the purity of the pulp and prolongs the life of the defibrator rotor and stator.5. Removes dirt and impurities, extending the life of the mesh and other machines.6. Maintains the lowest freeness, with fibers being undamaged, significantly improving pulp quality, paper uniformity, tear resistance, and fold resistance.7. Saves labor, as it can be integrated into an automatic pulping process, with compact equipment that occupies less space, high defibrating capacity, and good sand removal effect.8. For processing rice and wheat straw pulp, it can eliminate the need for trough-type pulpers and single or double disc grinding machines. Hydraulically breaking pulp and processing various waste papers through this equipment allows for direct paper making without further pulping.9. After vibrating frame screening, it processes rice and wheat straw pulp to dissolve undercooked straw and large fiber bundles, improving pulp yield, reducing bleaching rates, enhancing brightness, shortening pulping time, and protecting the CX screening machine and subsequent equipment.

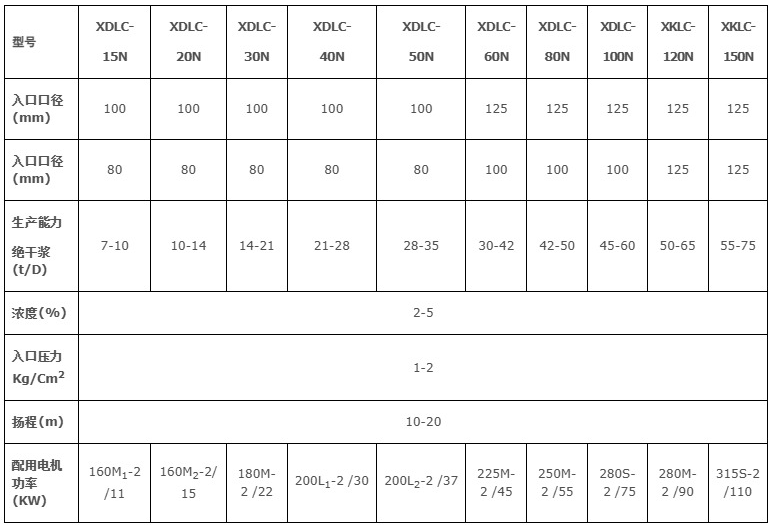

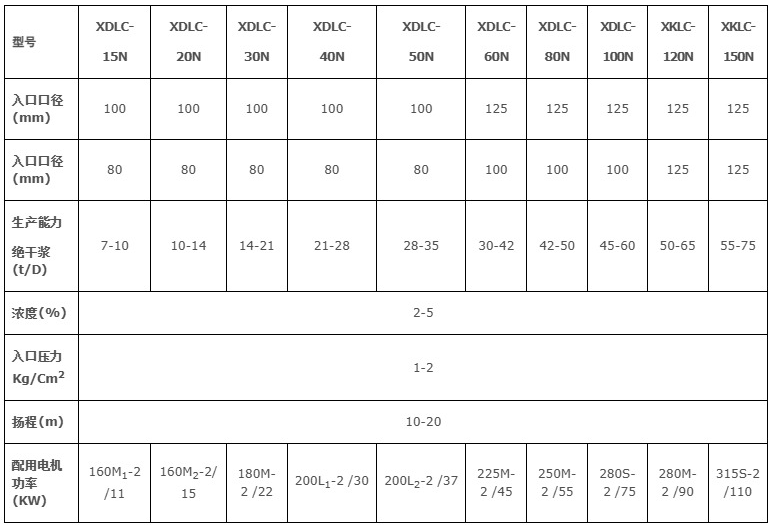

4. Parameter Selection.

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)