1. Product IntroductionThis machine is a horizontal single-direction pulping device, with radial discharge above. It mainly consists of a base, electric motor, machine housing, rotor, stator, feeding mechanism, and reduction mechanism. The machine adopts an integral base, providing good rigidity and stable operation. It is primarily used in the paper-making industry for coarse and fine grinding of pulps, as well as re-pulping of waste paper, particularly suitable for long-fiber pulps such as cotton, wood, and hemp. 2. Main Structure and Principle1. The machine is a horizontal, single-direction pulping device, with radial discharge above. It mainly consists of a base, electric motor, machine housing, rotor, stator, feeding mechanism, and reduction mechanism. The machine adopts an integral base, providing good rigidity and stable operation.

2. This mechanism uses both electric and manual feeding methods.(1) Pull out the toothed clutch opposite the handwheel, disconnecting the electric feeding mechanism. Manually turn the handwheel, moving the threaded sleeve axially via a worm gear mechanism, which adjusts the knife spacing and applies pressure for feeding.(2) Insert the toothed clutch, the electric feeding and retracting mechanism operates, driving the threaded sleeve for axial movement through the friction clutch gearbox to achieve feeding and retracting.(3) By adjusting the spring pressure of the friction clutch, the transmission power of the friction plates can be changed, allowing the equipment to operate under rated current, ensuring stable pulping quality.

3. Advantages of the Equipment1. It has a long grinding area and strong fiber cutting ability;2. It causes less damage to fine fibers, maintains good fiber shape and uniformity. After pulping, the paper has higher tear strength, breaking length, and burst resistance;3. Low energy consumption, high output, high efficiency, low noise, and easy maintenance.

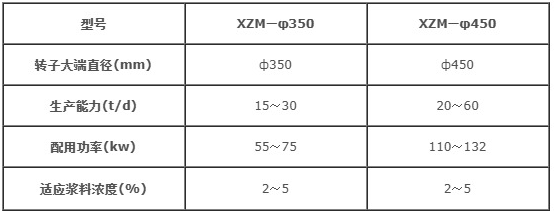

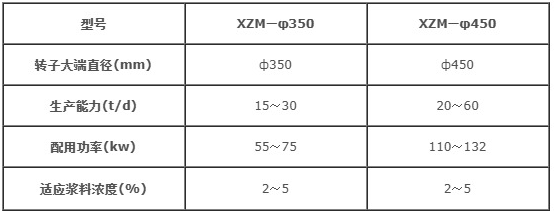

4. Equipped with manual and electric operating devices.4. Parameter Selection

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)