1. Product IntroductionThe XRDF type single-fiber separator is mainly used to separate light and heavy impurities from waste paper pulp and to perform secondary disintegration on the pulp coming from the hydraulic pulper. With the help of the secondary disintegration of this machine, the sieve holes of the bottom screen plate of the hydraulic pulper can be enlarged, thereby increasing its production capacity.

2. Equipment AdvantagesThis machine is essentially a combination of a sealed horizontal hydraulic pulper and a heavy-light impurity separator, featuring a compact structure and high efficiency. It integrates the functions of disintegration, impurity removal, and coarse screening, significantly simplifying the waste paper processing flow and reducing energy consumption.

3. Working PrincipleThe pulp enters the tank tangentially, where it accelerates downward by the impeller, creating a vortex within the tank. The centripetal force generated by the vortex causes light impurities to gather at the center of the vortex, while heavy impurities are thrown towards the tank wall. The light impurities that accumulate at the center of the tank are discharged through a discharge port for light impurities mounted on the front cover via a valve in a controlled manner, while the heavy impurities thrown to the tank wall, along with some pulp, continuously pass through the heavy impurity discharge pipe into the heavy impurity separator. The pulp, after being freed of heavy impurities, is sent back through the inlet pipe. The removed heavy impurities are collected in the separator's debris tank and discharged periodically through a valve.After secondary disintegration by the impeller in the tank, the pulp is sent out through the discharge pipe via the screen plate at the back of the impeller.

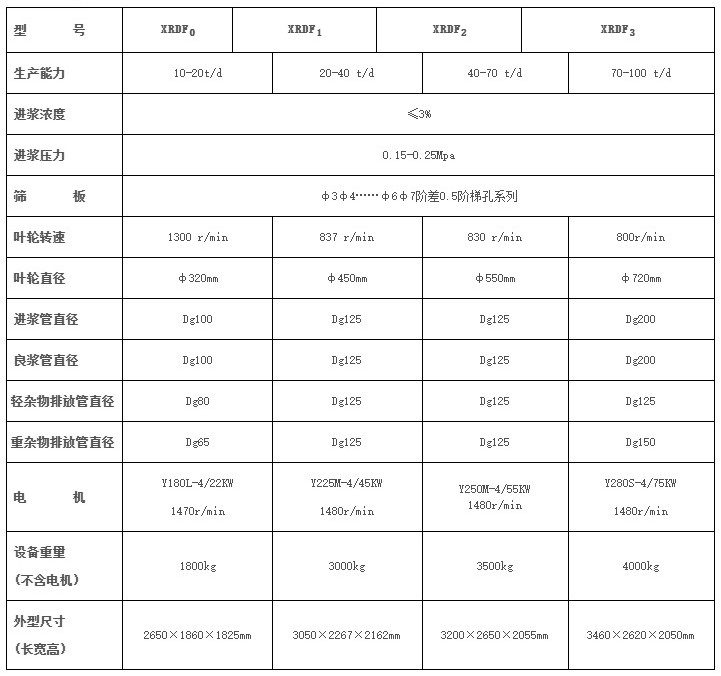

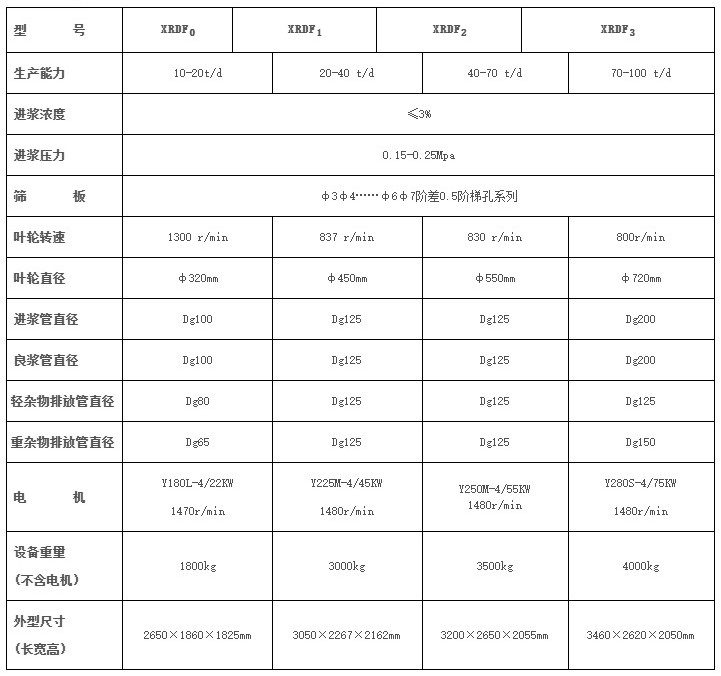

4. Parameter Selection

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)