1. Product IntroductionThe 400L-600L high-efficiency heavy-duty slag remover is a newly developed device based on advanced domestic and international technologies. It utilizes centrifugal principles to remove impurities from slurries, functioning as a forward slag remover. This product can be employed in various slurry purification systems to eliminate fine heavy impurities such as sand, iron filings, and dust, as well as larger ink particles in deinking systems.The heavy-duty slag remover can be combined with lightweight slag removers according to the type of slurry to achieve optimal purification results.

2. Operating Principle

A. Modular StructureThe slag remover features a modular design, allowing the entire device to be divided into 3-4 sections for easy assembly and replacement.

B. Different Slag Discharge MethodsThe heavy-duty slag remover can offer different discharge methods based on user requirements: pressure discharge or open discharge, to accommodate various work environments.

C. Ceramic Wear-Resistant Slag NozzleThe neck area of all centrifugal slag removers is where the tangential velocity is highest and wear is most concentrated. The lower cone of the heavy-duty slag remover uses a ceramic wear-resistant nozzle, ensuring a stable discharge rate and extending service life. Our company provides various forms and specifications of ceramic slag nozzles tailored to different discharge methods and user needs.

3. Advantages of equipment

1. Adopt advanced centrifugal purification technology, high efficiency, to ensure the cleanliness of pulping

2. Reduce pressure, reduce system power consumption, compact arrangement, and reduce floor space

3. Each slurry remover is equipped with valves for each slurry pipe, which reduces system downtime and increases system flexibility and reliability. 4. Ceramic wear-resistant slag remover nozzles of different forms and specifications can be selected according to different needs

5. The unfinished end is equipped with a ceramic pulp thinner, and different slag discharge methods are available for selection

6. Reinforced nylon material is durable

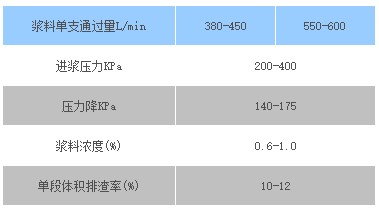

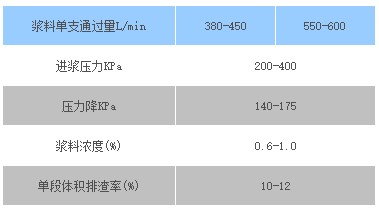

4. Parameter selection

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)