1. Product IntroductionThe ZSC series high-concentration sand separator is a state-of-the-art equipment developed through the digestion and absorption of technology imported from the United States, designed for effective purification of pulp.The high-concentration sand separator is an advanced device for pulp purification. It exploits the difference in specific gravity between fibers and impurities to separate heavier impurities from the pulp, achieving the goal of pulp purification. This equipment has a wide range of applications; it can be used for coarse purification of high-consistency pulp as well as for fine purification of low-consistency pulp before the paper machine. It is suitable for the production of chemical pulp, semi-chemical pulp, and mechanical pulp from waste paper, and is applied in the production of boxboard, corrugated paper, cultural paper, newsprint, and sanitary paper, particularly excelling in the purification of waste paper pulp and semi-chemical grass pulp.

2. Working PrincipleThe separator is composed of an imported head made of wear-resistant materials, a double-cone body, and a pneumatic control section. Under a certain pressure, the pulp enters the separator tangentially, utilizing the pressure difference between the inlet and outlet as power, causing the pulp to move in a spiral motion along the cone and generate centrifugal force. Under the influence of this centrifugal force, heavy impurities in the pulp are thrown against the inner surface of the upper cone and descend due to gravity, while the good pulp is discharged from the upper exit in the middle. Heavy impurities and some fibers settle into the lower cone, where they are backflushed by rinsing water, causing fibers to float to the upper cone for exclusion with the good pulp. The heavy impurities, after descending through the ball valve in the lower cone, accumulate in a sediment tank made of cast iron. The sediment tank is equipped with a water inlet, exhaust outlet, sludge discharge door, and observation window for cleaning, exhausting, observing, and discharging sludge. Additionally, the inlet has pressure gauges for monitoring inlet pressure and pressure difference during operation.

3. Equipment AdvantagesThis sand separator features a simple structure, a small footprint, high production capacity, easy operation, and it does not clog the sludge discharge port. The purification efficiency is high, with the pulp passing through the separator only once without the need for tail pulp treatment equipment. Fiber loss is zero, the cone is wear-resistant with a long service life, and it requires no transmission or power to achieve the separation effect during pulp transport.

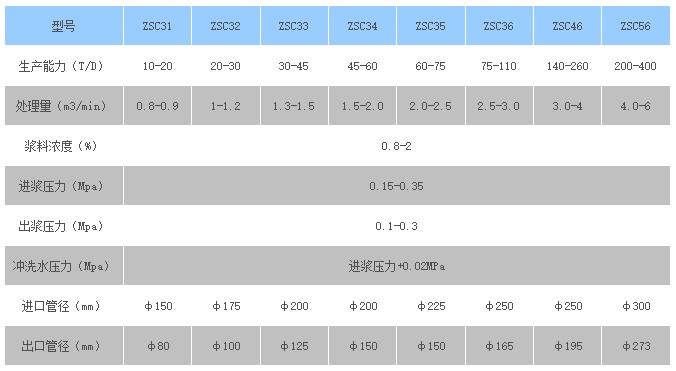

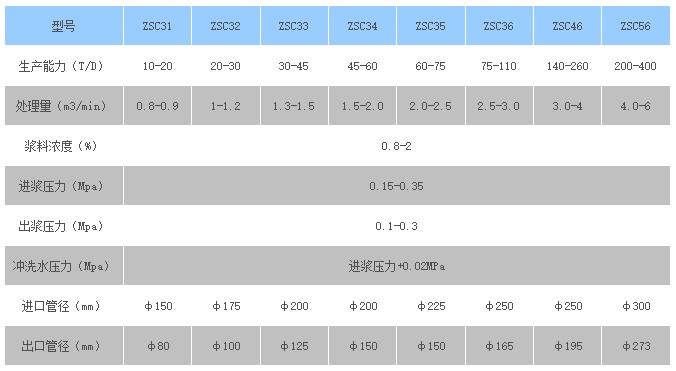

4. Parameter Selection

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)