1. Product IntroductionThe XZF series impurity separator is designed for the waste paper treatment process in the pulp and paper industry. It processes pulp that has been highly concentrated and disintegrated, collecting and concentrating impurities within the pulp to alleviate the burden on screening and purification equipment in subsequent operations. When used in conjunction with a high-concentration pulper, it shortens processing time, avoids the refinement of impurities, and enhances the production capacity of the disintegration system.This series of products operates after the high-concentration pulper. The pulp, after being diluted, enters the machine body under the influence of gravitational force. Due to the suction effect of the pump, the pulp passes through the screen plate into the good pulp chamber and is discharged through the pulp outlet. Light impurities are sent to the cylindrical screen for treatment under water pressure, recovering water and fiber while discharging heavy residues. The high-speed rotation of the rotor cleans the screen plate, preventing blockages of the screening holes; the special structure of the rotor avoids the refinement of debris.

2. Working PrincipleThe impurity separator features a specially designed low-friction blade hydraulic rotor, which ensures that the entering pulp is evenly dispersed, keeping the screen plate unblocked and preventing the breaking of impurities. Light impurities are discharged through the top outlet of the coarse separator, entering the cylindrical screen for further separation, while heavy impurities are discharged from the bottom of the coarse separator. The treated pulp after impurity removal is sent out via the discharge pipe from the rear screen plate.

3. Advantages of the Equipment

1. Effectively keeps the pulper chamber clean, obtaining pre-screened pulp.

2. Discharging pulp and removing impurities occur simultaneously.

3. Shortens processing time.

4. Enhances the production capacity of the pulping system.

5. The upward-tilted bottom surface of the impurity separator protects the rotor from damage by heavy impurities.

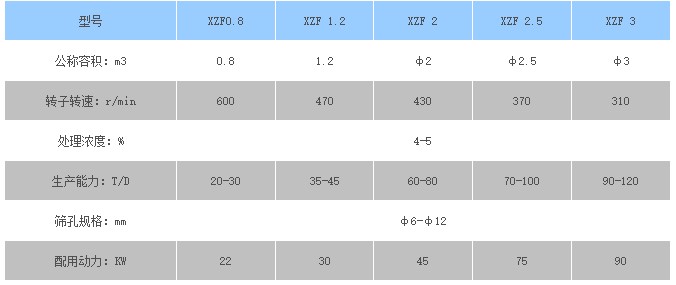

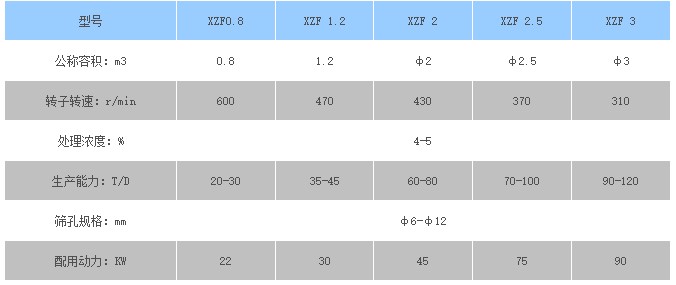

4. Parameter Selection

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)