1. Product IntroductionThe ZSC series medium-concentration sand remover is a high-efficiency slag removal equipment for pulp purification, successfully developed through the digestion and absorption of integrated selection technology and equipment.The medium-concentration sand remover is an advanced device for pulp purification. It separates heavy impurities from the pulp by utilizing the difference in specific gravity between fibers and impurities, thus achieving pulp purification. This equipment has a wide range of applications; it can be used for coarse selection purification of high-consistency pulp as well as for fine purification of low-consistency pulp prior to papermaking. It is applicable to the production of chemical pulp, semi-chemical pulp, as well as mechanical pulp waste paper, and is widely used in the production of boxboard paper, corrugated paper, cultural paper, newsprint, and sanitary paper. It is particularly effective in purifying waste paper pulp and semi-chemical grass pulp.

2. Working PrincipleThe sand remover is made of imported high-strength cast iron. Under pressure, the pulp enters the sand remover in a tangential direction, utilizing the pressure difference between the inlet and outlet as power to create a spiral motion along the cone, generating centrifugal force. Under the influence of this centrifugal force, heavy impurities in the pulp are thrown against the inner surface of the upper cone and move downward due to gravity, while good pulp is discharged through the central upper outlet. The heavy impurities and some fibers settle in the lower cone, where they are counter-flushed by wash water, causing the fibers to float to the upper cone, and the heavy impurities sink into the dregs tank made of cast iron via the ball valve at the bottom of the lower cone.

3. Equipment AdvantagesThis sand remover features a simple structure, occupies a small area, has a large production capacity, is easy to operate, and does not clog the slag discharge outlet. Its purification efficiency is high, as the pulp only passes through the sand remover once, eliminating the need for tail pulp treatment equipment. Fiber loss is zero, the cone is wear-resistant, has a long service life, and does not require drive power; it can simply be installed in the pulp transportation process to achieve the slag removal effect.

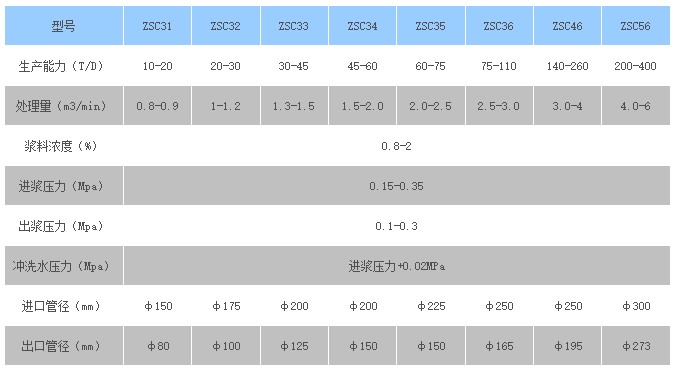

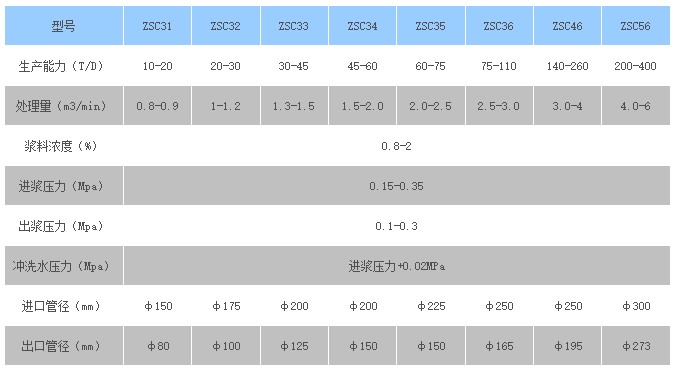

4. Parameter Selection

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)