I. Product IntroductionThe D-type hydrapulper is a modified version of the circular tank hydrapulper, specially designed for the disintegration of waste paper. The cross-sectional shape of the tank is "D" shaped. This unique shape alters the flow path of the pulp within the tank, moving the hydraulic vortex generated from the center to one side, allowing the pulp to be submerged quickly and facilitating more frequent and faster contact between the rotor and the pulp, thereby shortening the disintegration time and enhancing production capacity. The rotor and screen plate are elevated above the bottom of the tank, creating an area for heavy impurities to accumulate around the rotor. This reduces the frequency of contact between the rotor and impurities, increases disintegration efficiency, improves pulp quality, and prevents impurities from entangling the rotor.This equipment boasts strong disintegration capacity, short pulp time, easy operation and maintenance, and primarily performs a disintegration function without cutting the material.

2. Working PrincipleThe pulping action of the hydrapulper mainly results from the mechanical action of the blade of the impeller and the hydraulic shear effect caused by the rotation of the impeller. As the impeller rotates, the pulp, paper material, and water are drawn in along the central axis and rapidly flung out from the outer perimeter of the rotor, creating a turbulent circulation. Due to the impact, tearing, and significant friction between fluid layers at different flow velocities caused by the blades acting on the pulp, the pulp blocks and paper material are intensely crushed and disintegrated in the liquid state. Any unprocessed paper sheets or fiber bundles are further separated between the impeller blades and the screen plate, with compliant pulp flowing out of the pulper through appropriately sized screen holes.For large-scale processing projects, this equipment is typically used in conjunction with settling tanks, impurity separators, cylindrical screens, grapples, rope lift machines, etc. Users can also select the necessary supporting equipment according to their production capacity and processing requirements.

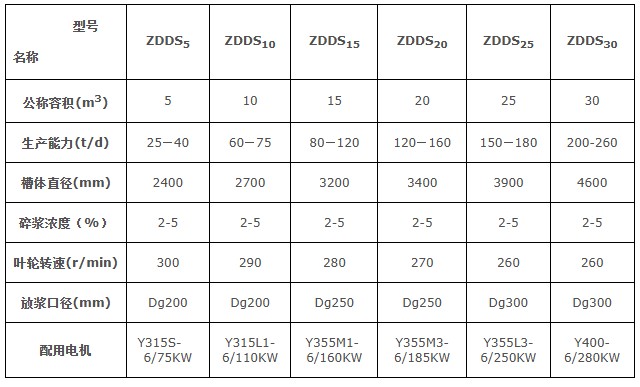

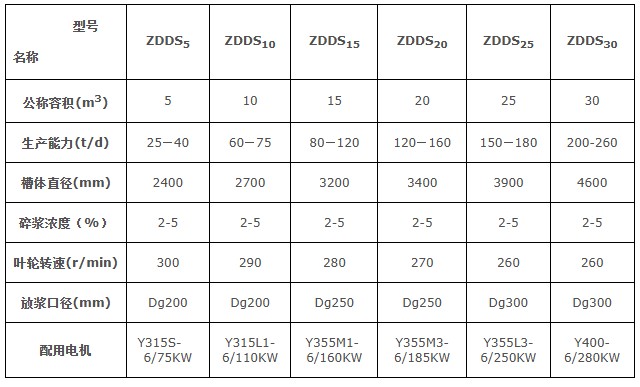

3. Parameter Selection

(2) (7).jpg)

(2) (13).jpg)

(3) (1).jpg)

(3)_(2).jpg)

(2) (4).jpg)

(2) (5).jpg)